Fuel Polishing

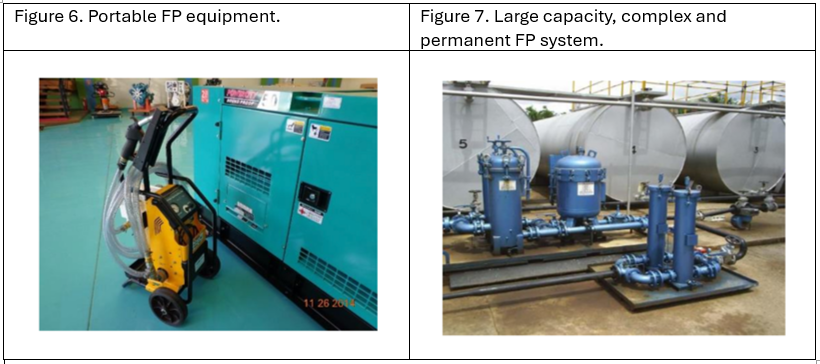

A fresh and clean diesel (Philippine B2 diesel) may look like a fresh cooking oil that is bright and clear yellow, Figure 1. After one month of outdoor storage and without human intervention diesel starts to turn brown. Figure 2. Air that enters into the vent carries oxygen causing oxidation that turns diesel into dark brown. Diesel molecules lengthen and bond to produce varnishes and insoluble gums. These particles then drop to the bottom of the tank to form asphaltene, also known as diesel sludge, Figure 3. This process is called re-polymerization of diesel. Further, diesel is hygroscopic. This means diesel is susceptible to attracting water molecules in the air from water vapor. Tank ullage is the usual space in tanks where moisture accumulates. Moisture carries water molecules that gradually drop onto diesel in the tank. Figure 4 shows water drained from a generator tank.

What is Fuel Polishing?

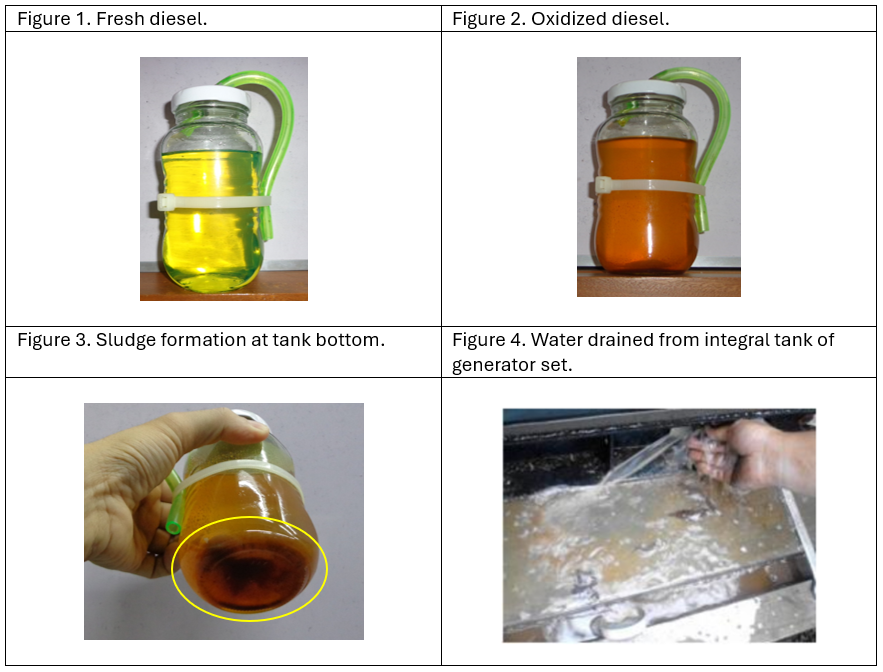

Fuel Polishing (Figure 5) is the removal of water, sediment, non-combustible particulate matter, and microbial contamination below levels stated in the ASTM D975 – Standard Specification for Diesel Fuel Oils while resuspending combustible particulate matter to maintain ASTM standards for BTU value, lubricity, and cetane. In simple terms, fuel polishing removes water, organic debris like bacteria and moss, and inorganic debris like dust and rust, and breaks down diesel byproducts by agitation.

Is Fuel Polishing effective in all contaminated diesel fuels?

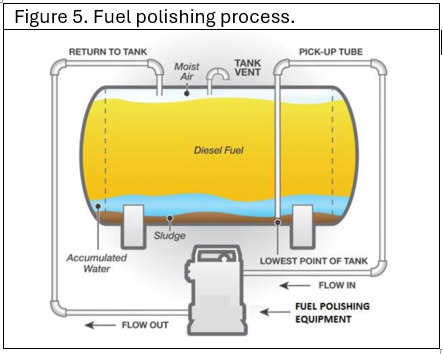

No. Not all fuel polishing systems are the same. Some fuel polishing systems are basic, compact, and portable with small single-stage filtration and water separation suitable for small tanks and fuels with minimal amount of contamination. Other fuel polishing systems are complex with large and multiple stages of filtration and water separation suitable for large tanks and fuels with high contamination.

Complex fuel polishing systems are most of the time ideal but expensive. This type of fuel polishing system is typically composed of the following stages:

Stage 1: Magnetic Filtration – provides bacterial neutralization for the fuel.

Stage 2: Centrifuge – removal of free water from fuel.

Stage 3: First Filtration – large particles are removed by 10 micron filter.

Stage 4: Second Filtration – medium particles are removed.

Stage 5: Coalescer – removal of emulsified water from fuel (99.8%)

Stage 6: Third Filter – absolute polishing by a 2-micron filter.